What is bonding?

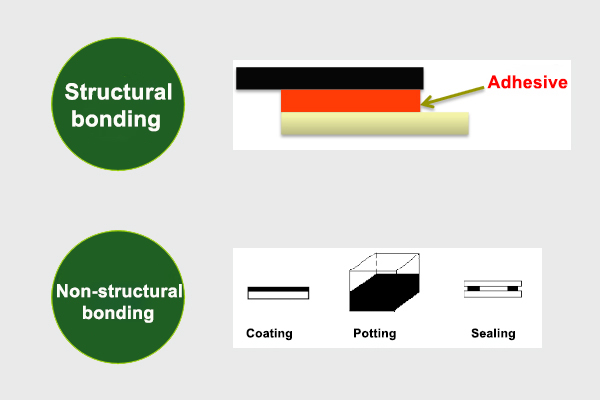

Bonding is a method of firmly connecting the same or different materials together using the adhesive force generated by adhesive glue on a solid surface. Bonding is divided into two types: structural bonding and non-structural bonding.

What are the functions of adhesive?

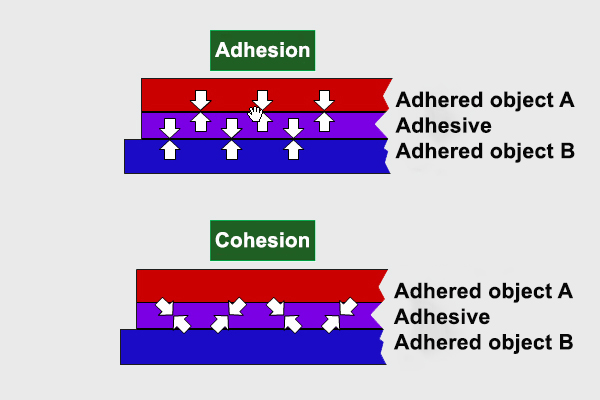

The bonding adhesive relies on the interaction of the bonding interface, and connects specific homogeneous or heterogeneous and complex shaped objects or devices through a simple process method, while giving some special functions, such as sealing, insulation, heat conduction, electricity conduction, magnetic permeability, filling, buffering, protection and so on. The two core of bonding are adhesion and cohesion. Adhesion refers to the attraction between two different surfaces, and cohesion refers to the attraction between the molecules of the material itself.

What are the common bonding methods?

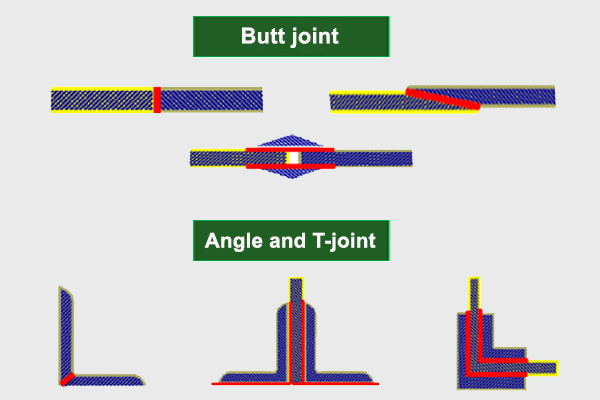

1. Butt joint: The ends of two substrates coated with adhesive are bonded together, and the bonding contact area is small.

2.Corner joint and T- joint: It is connected by the end of one base material and the side of another base material.

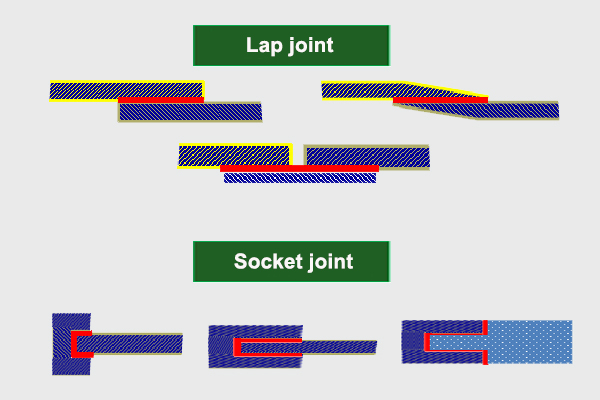

- 3. Lap joint (flat joint): It is connected by the sides of the base material, and the bonding area is larger than the butt joint.

- 4. Socket (embedded) joint: insert one end of the connection into the gap or punched hole at the other end for bonding, or use a sleeve to connect.

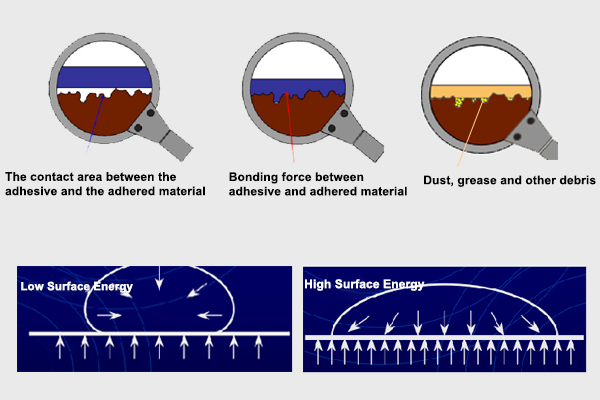

What are the factors that affect the bonding effect?

1. Material to be bonded: surface roughness, surface cleanliness and polarity of the material, etc.;

2. Bonding joints: length, adhesive layer thickness and different forms of joints;

3. Environment: the environment (heat/water/light/oxygen, etc.), temperature and temperature changes of the gluing site;

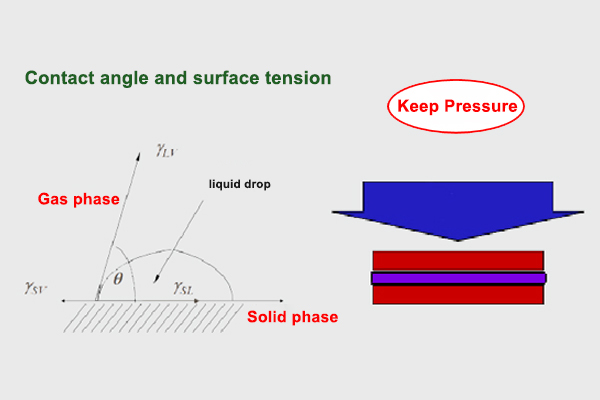

4. Adhesive: chemical structure, penetration, migration, curing method, pressure, etc.;

What are the reasons for bonding failure?

There are many reasons for bonding failure, which require detailed analysis of specific situations. Common reasons include the following:

1. The adhesive and the base material do not match, such as: cracking occurs between ethanol removal and the PC base material;

2. Surface contamination: Release agents affect bonding, flux affects three preventions, potting poisoning, etc.;

3. Short bonding time/insufficient pressure: Insufficient pressure or pressure holding time results in poor bonding effect;

4. Effect of temperature/humidity: solvent evaporates quickly and structural adhesive solidifies too quickly;

It can be seen that a suitable bonding glue solution must not only take into account the material, shape, structure and gluing process of the bonded parts, but also consider the load and form of the various bonded parts as well as the surrounding environment. Influencing factors, etc. If you have anything you don’t understand or need adhesive sealant, please contact Siway.

Post time: Dec-27-2023