1. Overview of insulating glass

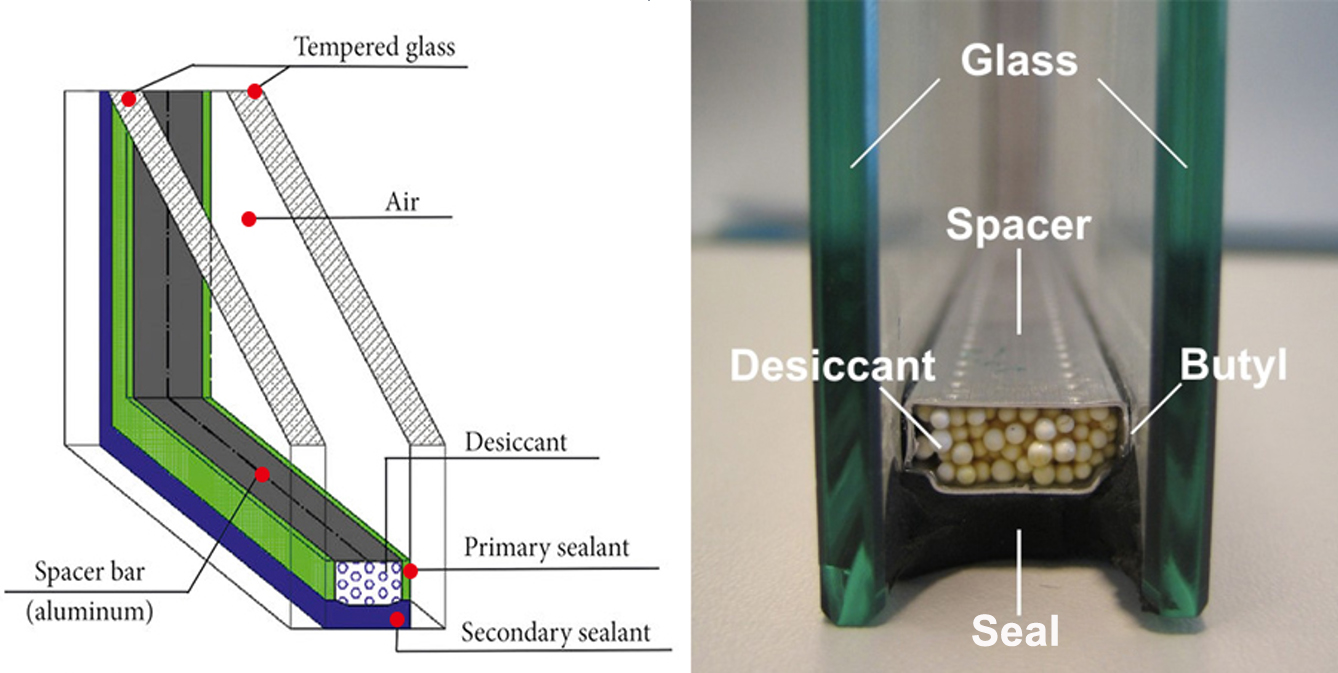

Insulated glass is a type of energy-saving glass that has been widely used in commercial office buildings, large shopping malls, high-rise residential buildings and other buildings. It has excellent heat insulation and sound insulation properties and is beautiful and practical. Insulated glass is made up of two (or more) pieces of glass bonded with spacers. There are two main types of sealing: the strip method and the glue bonding method. At present, the double seal in the glue bonding method is the most commonly used sealing structure. The structure is as shown in Figure 1: two pieces of glass are separated by spacers, and butyl sealant is used to seal the spacer and glass in the front. Fill the interior of the spacer with molecular sieve, and seal the gap formed between the edge of the glass and the outside of the spacer with a secondary sealant.

The function of the first sealant is to prevent water vapor or inert gas from entering and exiting the cavity. Butyl sealant is generally used because the water vapor transmission rate and inert gas transmission rate of butyl sealant are very low. However, butyl sealant itself has low bonding strength and low elasticity, so the overall structure must be fixed with a second sealant to bond the glass plates and spacers together. When the insulating glass is under load, a layer of sealant can maintain a good sealing effect. At the same time, the overall structure is not affected.

Figure 1

2. Types of secondary sealants for insulating glass

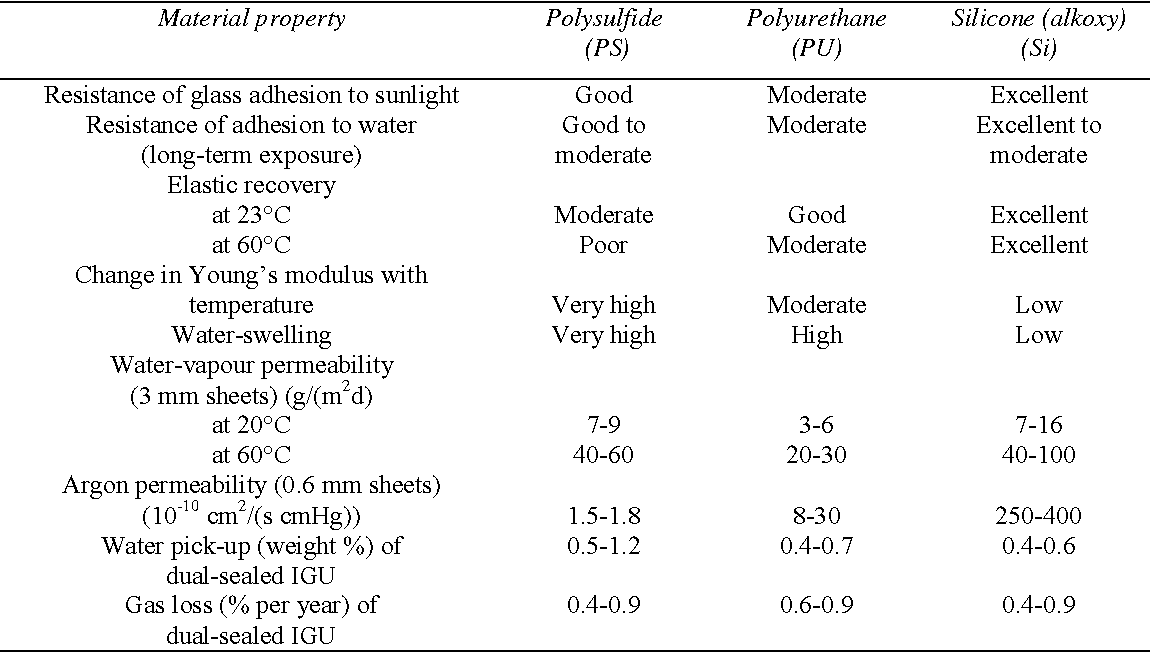

There are three main types of secondary sealants for insulating glass: polysulfide, polyurethane and silicone. Table 1 lists some characteristics of the three types of sealants after they are fully cured.

Table 1 Comparison of performance characteristics of three types of secondary sealants for insulating glass

The advantage of polysulfide sealant is that it has low water vapor and argon gas transmittance at room temperature; its disadvantage is that it has high water absorption rate.

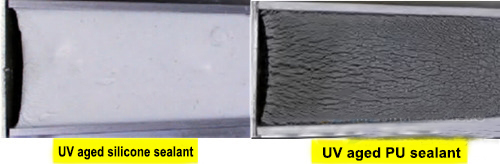

The modulus and elastic recovery rate decrease greatly as the temperature increases, and the water vapor transmittance is also very large when the temperature is high. In addition, due to its poor UV aging resistance, long-term UV irradiation will cause non-stick degumming.

The advantage of polyurethane sealant is that its water vapor and argon gas transmittance is low, and the water vapor transmittance is also relatively low when the temperature is high; its disadvantage is that it has poor UV aging resistance.

Silicone sealant refers to a sealant with polysiloxane as the main raw material, also called agricultural production system silicone sealant. The polymer chain of silicone sealant is mainly composed of Si-O-Si, which is cross-linked to form a network-like Si-O-Si skeleton structure during the curing process. The Si—O bond energy (444KJ/mol) is very high, not only much larger than other polymer bond energies, but also larger than ultraviolet energy (399KJ/mol). The molecular structure of silicone sealant enables silicone sealant to have excellent high and low temperature resistance, weather resistance and UV aging resistance, as well as low water absorption. The disadvantage of silicone sealant when used in insulating glass is high gas permeability.

3. Correct selection of secondary sealant for insulating glass

If the bonding surface of polysulfide glue, polyurethane glue and glass is exposed to sunlight for a long time, degumming will occur, which will cause the outer piece of the insulating glass of the hidden frame glass curtain wall to fall off or the sealing of the insulating glass of the point-supported glass curtain wall to fail. Therefore, the secondary sealant for insulating glass of hidden frame curtain walls and semi-hidden frame curtain walls must use silicone structural sealant, and the interface size must be calculated according to JGJ102 "Technical Specifications for Glass Curtain Wall Engineering";

The secondary sealant for insulating glass of point-supported glass curtain walls must use silicone structural sealant; for the secondary sealant of insulating glass for large-size open frame curtain walls, it is recommended to use insulating glass silicone structural sealant. The secondary sealant for insulated glass for doors, windows and ordinary open-frame curtain walls can be insulated glass silicone sealant, polysulfide sealant or polyurethane sealant.

Based on the above, users should choose the appropriate secondary sealant product for insulating glass according to the specific application of the insulating glass. On the premise that the sealant quality is qualified, as long as it is selected and used properly, insulating glass can be produced with a service life that meets the usage requirements. But if improperly selected and used, even the best sealant may produce insulating glass of substandard quality.

When selecting the secondary sealant, especially the silicone structural sealant, we must also consider that the silicone sealant must meet the functional requirements of the insulating glass, the compatibility with the primary sealing butyl sealant, and the performance of the silicone sealant should meet the requirements of relevant standards. At the same time, the quality stability of silicone sealant products, the popularity of silicone sealant manufacturers, and the manufacturer's technical service capabilities and levels in the entire process of pre-sales, sales, and after-sales are also important factors that users need to consider.

Insulating glass sealant accounts for a low proportion of the entire insulating glass manufacturing cost, but it has a great impact on the quality and service life of insulating glass. Insulating glass structural sealant is even directly related to curtain wall safety issues. At present, as the competition in the sealant market becomes increasingly fierce, some sealant manufacturers do not hesitate to sacrifice product performance and quality when reducing costs in order to win customers at low prices. A considerable number of low-quality and low-price insulating glass sealant products have appeared on the market. If the user chooses it carelessly, in order to save a little cost of sealant, it may cause safety hazards or even lead to quality accidents, which may cause heavy losses.

Siway hereby urges you to choose the right product and good product; at the same time, we will introduce to you the various hazards caused by using low-quality insulating glass secondary sealant and improper use in the future.

Post time: Dec-13-2023