With the continuous deepening of industrialization, electronic equipment is rapidly developing in the direction of miniaturization, integration and precision. This trend of precision makes the equipment more fragile, and even a small fault may seriously affect its normal operation. At the same time, the application scenarios of electronic equipment are also expanding. From Gobi, desert to ocean, electronic equipment is everywhere. In these extreme natural environments, how to effectively resist harsh conditions such as ultraviolet radiation, high temperature exposure, acid rain erosion, etc. has become an urgent problem to be solved.

Adhesives, known as "industrial MSG", not only have good bonding properties, but also have certain strength and hardness after curing, so it is also a very effective protective material. Potting & Encapsulation, as an adhesive with flow properties, its core role is to effectively fill the gaps of precision components, tightly wrap the components, and form a strong protective barrier. However, if an inappropriate potting adhesive is selected, its effect will be greatly reduced.

Common Problems

Common problems of electronic potting adhesive are as follows:

Brittleness

Debonding

Yellowing

1. Brittleness: The colloid gradually loses its elasticity and cracks under long-term high temperature and high humidity environment.

2. Debonding: The colloid structure gradually detaches from the surface of the junction box, resulting in bonding failure.

3. Yellowing: A common aging phenomenon that affects appearance and performance.

4. Degradation of insulation performance: Causes electrical failures and seriously affects the safety of the system.

A high-quality adhesive is essential.

Excellent silicone potting adhesive is the key to solving the problem!

With its natural weather resistance and durability, silicone potting adhesive can effectively protect electronic components for a long time, thereby extending their service life. SIWAY's electronic thermal conductive potting adhesive not only has the basic functions of adhesives, but also has excellent weather resistance and aging resistance, mainly including the following aspects:

Insulation and thermal conductivity flame retardant performance: Effectively protect the inside of the junction box to prevent accidents such as short circuit burning.

Waterproof and moisture-proof: Prevent water vapor from entering the inside of the junction box to prevent problems such as electrical short circuits.

Excellent bonding: Good bonding performance for materials such as PPO and PVDF.

In order to better evaluate the performance of potting adhesive, aging testing is essential. In the industrial field, aging tests include: UV aging, hot and cold cycles, hot and cold shock, high temperature and high humidity aging (usually 85℃, 85%RH, double 85), and high accelerated temperature and humidity stress test (High Accelerated Stress Test, HAST). Double 85 and HAST are the two fastest and most effective aging test methods. They can quickly accelerate material aging through extreme environments of high humidity, heat and high pressure, predict the life and reliability of products in different environments, and provide a basis for product design and optimization.

Good or not, only testing can tell

Let's take a look at SIWAY silicone potting adhesive performance in double 85 and HAST tests.

Double 85 test usually refers to accelerated aging test performed at 85°C and 85% relative humidity. This test is designed to simulate the conditions of long-term use of electronic components in a humid and high temperature environment to evaluate their performance and reliability.

HAST(Humidity Accelerated Stress Test) is an accelerated aging test, usually performed under high temperature and high humidity conditions to accelerate the aging process of materials and components.

1. Appearance changes:

After double 85 1500h and HAST 48h tests, the surface of the sample will not turn yellow, and there will be no surface damage or cracks. It is essential for the long-term operation of electronic systems to effectively resist the influence of external factors on its appearance under high temperature and high humidity conditions.

Normal

Double 85 test

HAST

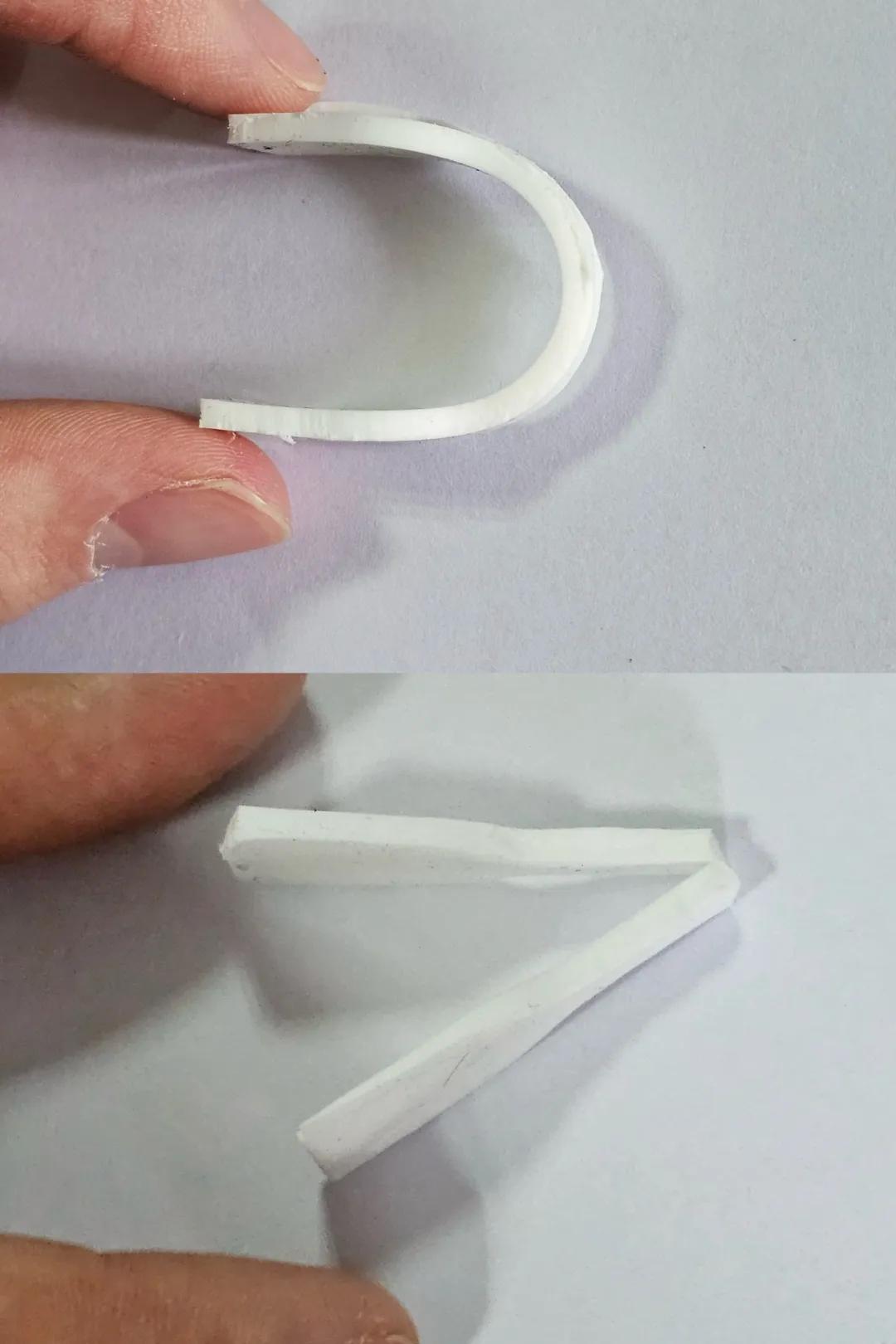

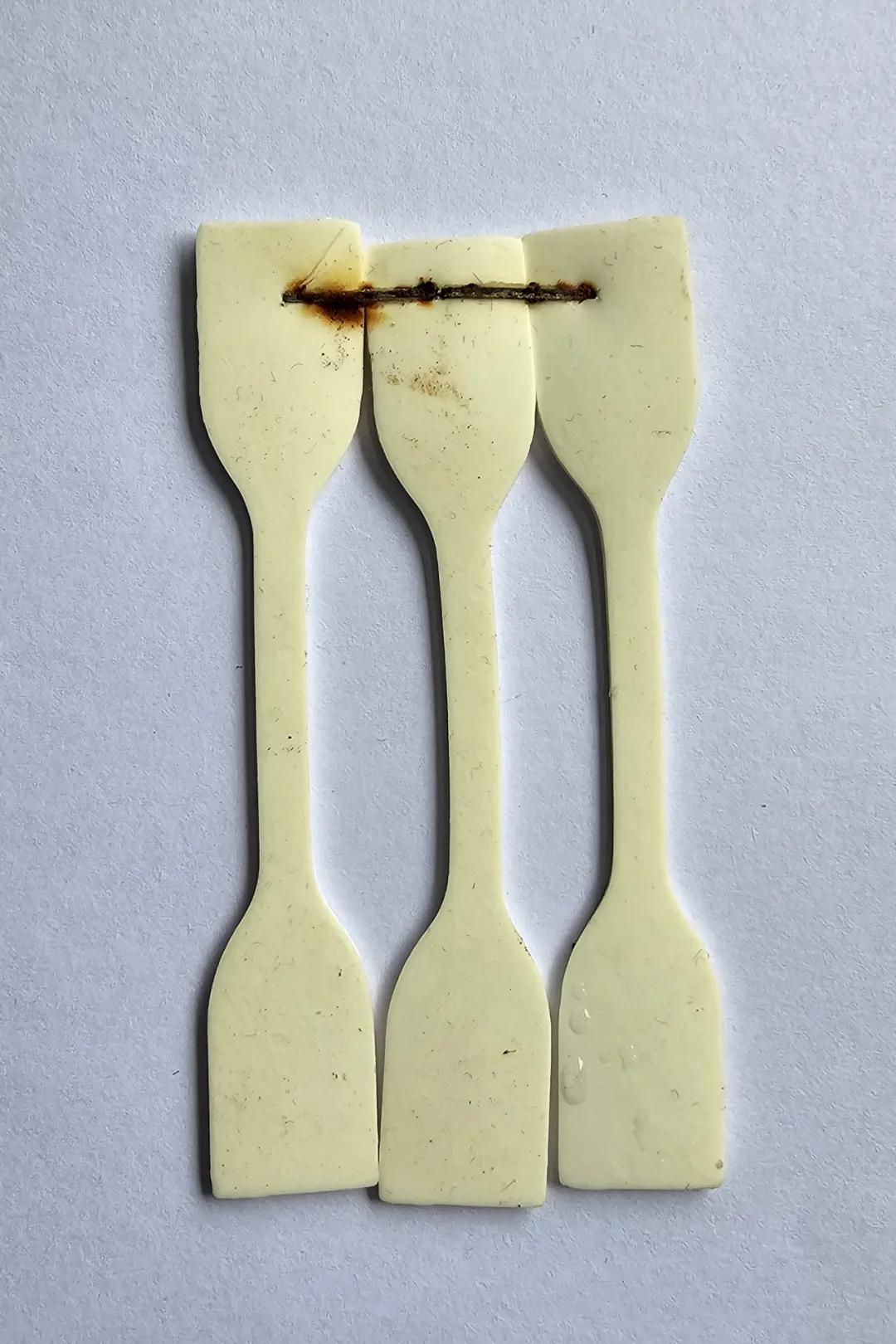

2. Adhesion ability:

After the double 85 1500h and HAST 48h tests, the adhesion ability of SIWAY silicone potting adhesive is still good. It has excellent adhesion in extreme environments, which can effectively ensure the waterproof and moisture-proof effects in key components of the system and ensure that electronic components are protected for a long time.

3. Physical mechanical and electrical properties:

After the double 85 and HAST aging tests, the physical mechanical and electrical properties of Silicon siway are maintained at a high level. It has high toughness, elasticity and insulation performance. It can effectively resist the external environment in extreme environments and provide reliable protection for electronic components.

Post time: Nov-27-2024