For over three decades, Shanghai Siway Building Materials Co., Ltd. has solidified its reputation as one of Shanghai’s TOP3 adhesive and sealant manufacturers, delivering precision-engineered solutions to industries worldwide. Established in 1984, SIWAY combines cutting-edge R&D, vertically integrated production, and uncompromising quality control to address complex sealing challenges across construction, automotive, electronics, and renewable energy sectors.

Why SIWAY Ranks Among the Best Sealant Manufacturers

1. State-of-the-Art Manufacturing Infrastructure

Spanning 220,000 m², SIWAY’s industrial base houses 12 fully automated, AI-driven production lines capable of producing 120,000 metric tons annually. This advanced setup ensures:

- Zero-defect output: Laser-guided precision dispensing and real-time viscosity monitoring.

- Agile customization: Rapid formulation adjustments for UV-resistant, high-temperature, or low-VOC sealants.

- Sustainability: Closed-loop recycling systems reduce waste by 30%, aligning with global ESG standards.

2. 30+ Years of Silicone Sealant Expertise

SIWAY’s legacy includes breakthroughs such as:

- Patented hybrid silicone-polyurethane adhesives for aerospace applications (ISO 10993-certified).

- Self-healing silicone sealants that repair micro-cracks, extending service life by 40%.

- Flame-retardant formulations compliant with UL 94 V-0 and GB 8624-2012 standards.

3. Global Trust Across 50+ Countries

From Dubai’s Burj Khalifa to Tesla’s EV battery assembly lines, SIWAY products are chosen for:

- Weatherproofing: Withstand -50°C to 300°C, ideal for Arctic pipelines or desert solar farms.

- Chemical resistance: ASTM C920-certified against acids, alkalis, and industrial solvents.

- Long-term adhesion: 98% bond retention after 20 years in accelerated aging tests.

Shanghai Siway’s leadership in the adhesive and sealant industry stems from three pillars of excellence: advanced manufacturing, decades of R&D innovation, and globally proven performance. These strengths not only define our market position but also directly influence the quality and versatility of our sealant types—ensuring solutions that meet the highest durability demands.

What Are the Three 3 Types of Sealants? Industry Insights from SIWAY

Understanding why SIWAY is a top manufacturer requires a closer look at our core product range. We specialize in engineering three primary sealant categories, each tailored to address specific industrial challenges:

1.Silicone Sealants

- Applications: Structural glazing, medical device assembly, photovoltaic panel sealing.

- Advantages: UV stability (ASTM G154), thermal cycling resistance, and FDA compliance for food-grade uses.

2.Polyurethane Sealants

- Applications: Automotive windshield bonding, bridge expansion joints, soundproofing.

- Advantages: Elastic recovery >90% (ISO 8339), tear strength up to 45 N/mm.

3.Acrylic Sealants

- Applications: Interior drywall sealing, HVAC ductwork, decorative trims.

- Advantages: Low odor, paintable surfaces, and rapid curing (24-hour handling time).

How Many Years Does Sealant Last? Maximizing Durability with SIWAY

High-performance sealants typically last 15–25 years, but SIWAY’s formulations push boundaries:

- Silicone sealants: 25+ years in coastal areas (tested per ASTM C794 salt spray standards).

- Polyurethane sealants: 20+ years on high-movement substrates (tested at ±50% joint elongation).

- Acrylic sealants: 15+ years indoors with humidity control.

Key Factors Influencing Lifespan:

- Surface preparation: SIWAY’s proprietary primers boost substrate adhesion by 70%.

- Curing conditions: Our moisture-cure silicones adapt to 30–98% relative humidity.

- Maintenance protocols: Download SIWAY’s Free Sealant Lifespan Calculator for predictive upkeep schedules.

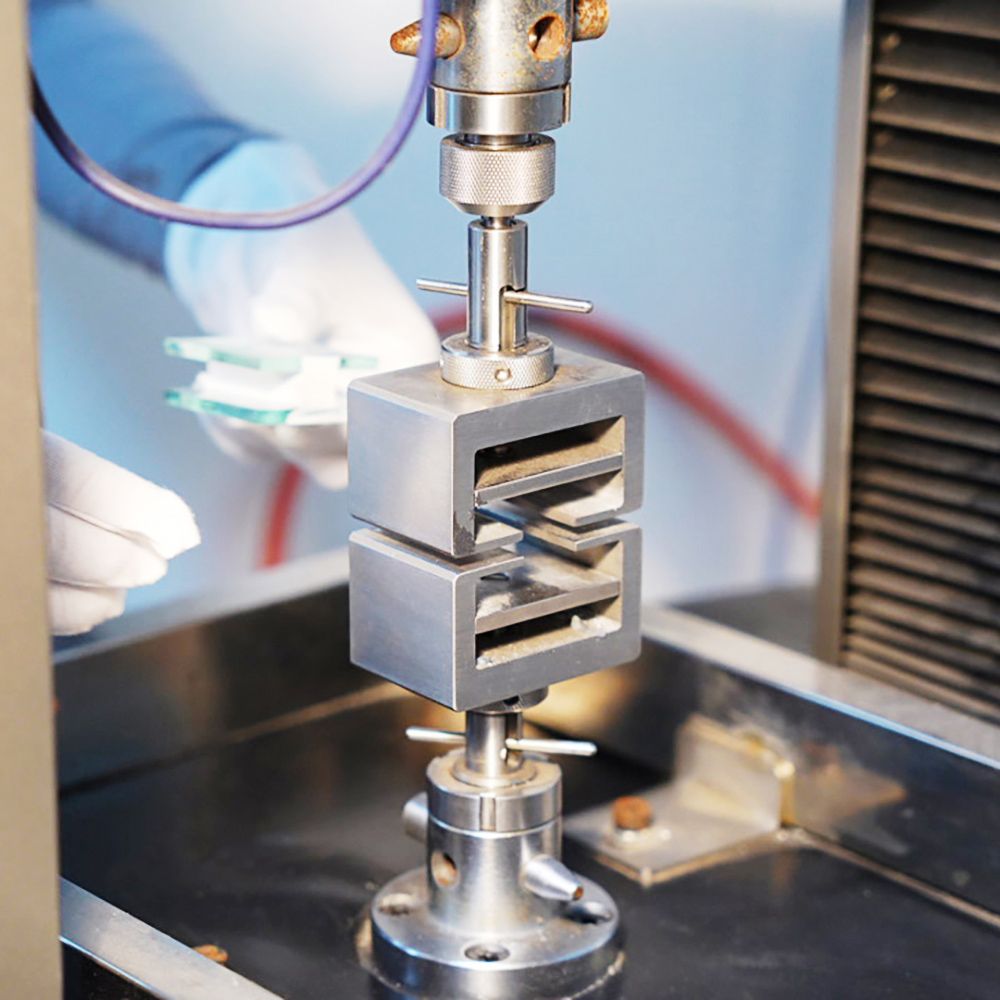

SIWAY’s Quality Assurance: From Lab to Global Delivery

- Raw Material Sourcing: Partnering with Dow Corning and Evonik for medical-grade silicones.

- In-process testing: FTIR spectroscopy and rheology analysis ensure batch consistency.

- Certifications: ISO 9001, ISO 14001, and REACH compliance for EU/US markets.

Awarded “Market Excellence Award” by China Building Materials Association, SIWAY’s 24/7 technical support team assists engineers in selecting sealants based on:

- Shore hardness (A20 to A80).

- Modulus (high vs. low movement).

- Coefficient of thermal expansion (CTE matching).

Contact Us ! Get free sample !

Post time: Mar-12-2025