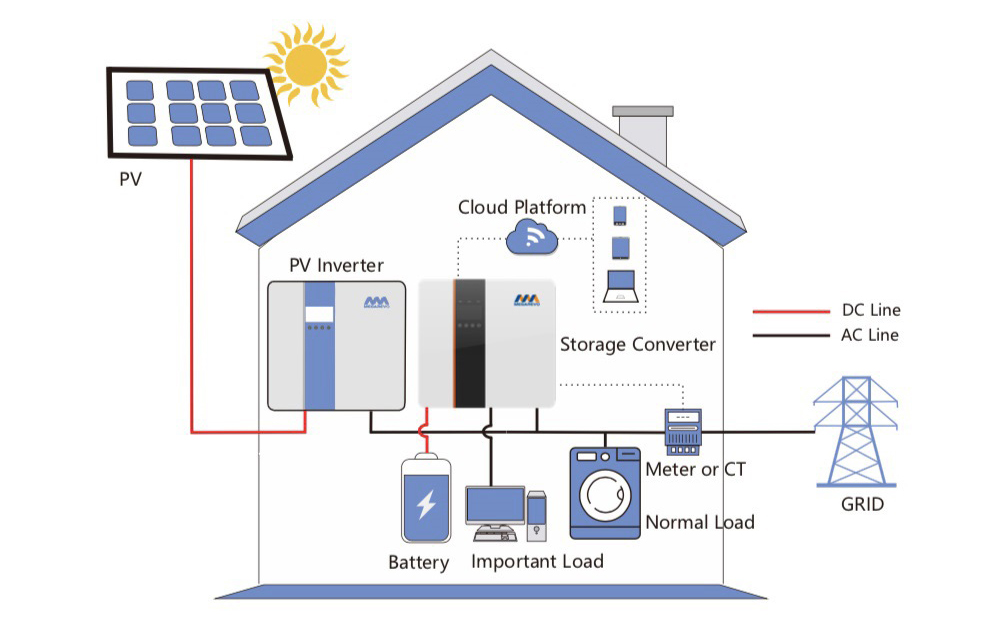

As the demand for renewable energy sources continues to grow, the need for efficient and reliable energy storage solutions becomes increasingly important. Storage inverters play a crucial role in this regard, converting direct current (DC) from renewable energy sources into alternating current (AC) for use in homes and businesses. To ensure seamless operation and optimal performance, the use of high-quality adhesive materials in storage inverters is of utmost significance. In this essay, we will explore the importance of storage inverter adhesive, its benefits, and its impact on the overall efficiency and reliability of renewable energy systems.

The Role of Adhesive in Storage Inverters

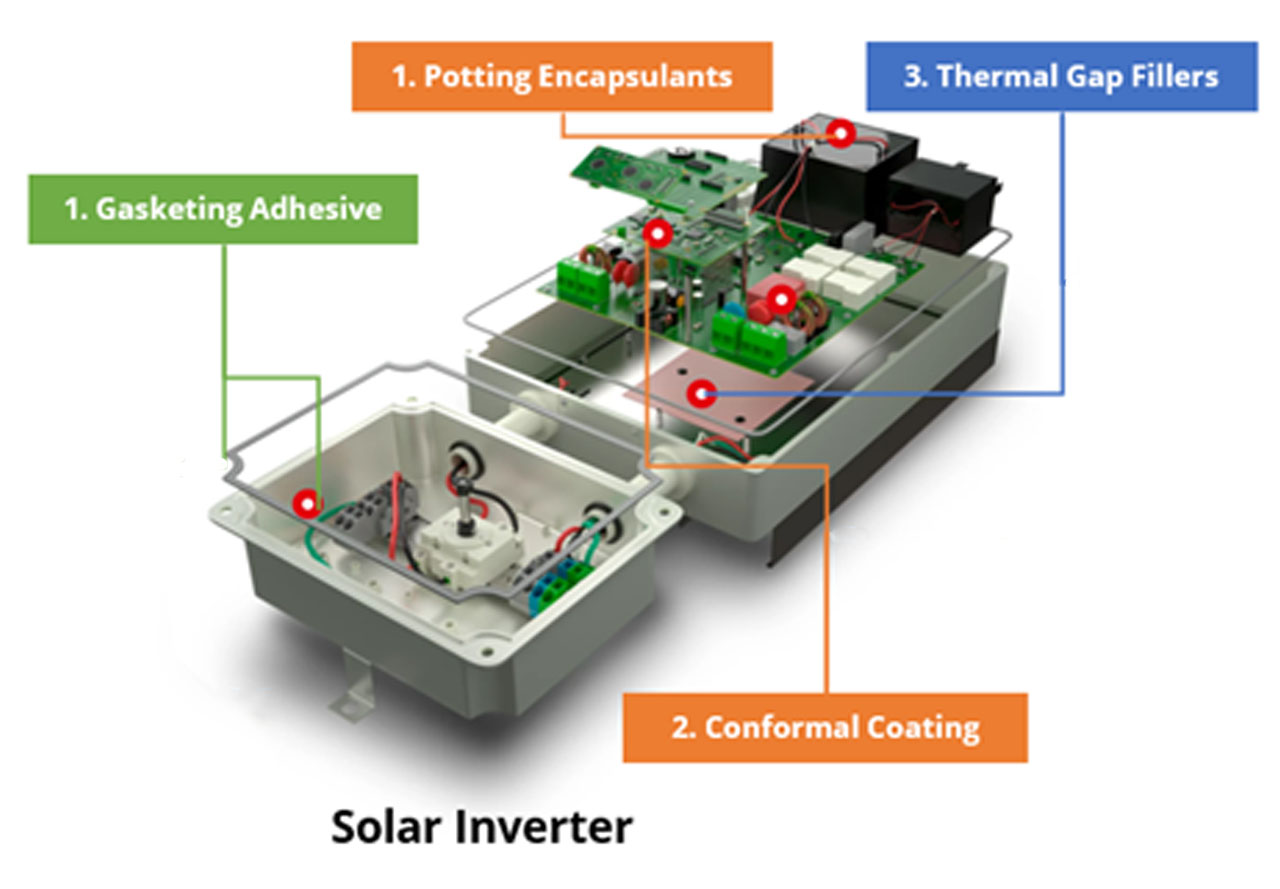

Storage inverters consist of multiple components, including semiconductors, capacitors, and printed circuit boards (PCBs). These components need to be securely bonded together to create a robust and reliable system. Adhesive materials are used to join these components, providing mechanical stability, electrical insulation, and thermal management. The adhesive not only holds the components in place but also enhances heat dissipation, preventing overheating and ensuring optimal performance.

Benefits of High-Quality Adhesive in Storage Inverters

1. Enhanced Reliability: High-quality adhesive materials offer excellent bonding strength, ensuring that the components remain securely attached even under harsh operating conditions. This reduces the risk of component failure and system downtime, resulting in increased reliability of the storage inverter.

2. Improved Efficiency: Adhesive materials with good thermal conductivity help in efficient heat dissipation, preventing hotspots and thermal stress. This ensures that the storage inverter operates within its optimal temperature range, leading to improved efficiency and performance. Additionally, adhesive materials with low electrical resistance minimize power losses, further enhancing the overall efficiency of the system.

3. Longevity: Storage inverters are expected to have a long lifespan to maximize the return on investment. High-quality adhesive materials offer excellent resistance to environmental factors such as temperature variations, humidity, and UV radiation. This resistance ensures the longevity of the adhesive bond, preventing degradation and maintaining the performance of the storage inverter over an extended period.

4. Safety: Adhesive materials play a crucial role in ensuring the safety of the storage inverter. They provide electrical insulation, preventing short circuits and minimizing the risk of electrical hazards. Additionally, high-quality adhesives are often flame-retardant, reducing the risk of fire and enhancing the overall safety of the renewable energy system.

Impact on Renewable Energy Systems

The use of high-quality adhesive in storage inverters has a significant impact on the overall efficiency and reliability of renewable energy systems. By ensuring secure bonding and efficient heat dissipation, the adhesive materials contribute to the longevity and optimal performance of the storage inverter. This, in turn, maximizes the energy conversion efficiency, reduces maintenance costs, and enhances the return on investment for renewable energy system owners. Furthermore, the reliability and safety provided by high-quality adhesive materials instill confidence in end-users, promoting the adoption of renewable energy technologies and contributing to a sustainable future.

In conclusion, the use of high-quality adhesive materials in storage inverters is essential for enhancing the efficiency and reliability of renewable energy systems. The adhesive provides secure bonding, efficient heat dissipation, and electrical insulation, ensuring optimal performance and longevity of the storage inverter. As the demand for renewable energy continues to rise, it is imperative for manufacturers and researchers to focus on developing and utilizing advanced adhesive materials that can withstand the demanding operating conditions of renewable energy systems. By doing so, we can accelerate the transition towards a clean and sustainable energy.

Post time: Sep-21-2023