SV 709 Silicone Sealant for solar photovoltaic assembled parts

FEATURES

1.Excellent bonding properties, good adhesion to the aluminum, glass, composite back plate, PPO and other materials.

2.Excellent electrical insulation and weather resistance, could be used in -40 ~ 200℃.

3.Neutral cured, non-corrosive to a lot of materials, resistant to ozone and resistant to chemical corrosion.

4.Passed the double "85" high temperature and humidity test, aging test, hot and cold temperature impact test. Resistant to yellowing, environmental corrosion, mechanical shock, thermal shock, vibration and so on.

5.Passed TUV, SGS, UL, ISO9001/ISO14001 Certification.

ADVANTAGE

1. Good sealing, the aluminum, glass, TPT / TPE back material, junction box plastic PPO / PA have good adhesion;

2. A unique curing system, measured by high temperature and humidity ring, with all types of EVA have good compatibility;

3. The unique rheological system, the colloid of the fine, good resistance to deformation ability;

4. Flame retardant performance to UL 94-V0 the highest level;

5. In full compliance with the EU ROHS environmental directive requirements, SGS-related test reports.

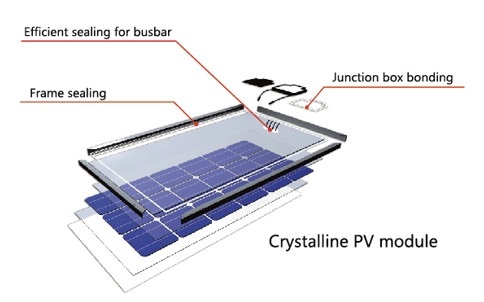

6.Typical applications: Solar panel bonding, PV module aluminum frame sealing and junction box and TPT / TPE back film adhesive seal.

TECHNICAL DATA

| Products | JS-606 | JS-606CHUN | Test Methods |

| color | White/black | White/black | Visual |

| g/cm3 Density | 1.41±0.05 | 1.50±0.05 | GB/T 13477-2002 |

| Solidification type | oxime | /alkoxy | / |

| Tack-Free Time, min | 5~20 | 3~15 | GB/T 13477 |

| Durometer hardness, 邵氏 A | 40~60 | 40~60 | GB/T 531-2008 |

| Tensile strength, MPa | ≥2.0 | ≥1.8 | GB/T 528-2009 |

| Elongation at Break, % | ≥300 | ≥200 | GB/T 528-2009 |

| Volume resisitivity, Ω.cm | 1×1015 | 1×1015 | GB/T1692 |

| disruptive strength,KV/mm | ≥17 | ≥17 | GB/T 1695 |

| W/m.k Thermal conductivity | ≥0.4 | ≥0.4 | ISO 22007-2 |

| Fire resistance,UL94 | HB | HB | UL94 |

| ℃ Working temperature | -40~200 | -40~200 | / |

All the parameters are tested after curing 7 days in 23±2℃,RH 50±5%.The datas in the table are only suggestions.

PRODUCT INTRODUCTION

Safety Application

All surfaces must be clean and dry. Degrease and wash off any contaminants that could impair adhesion. Suitable solvents include isopropyl alcohol, acetone, or methyl ethyl ketone.

Not contact eyes with uncured sealant and wash by water once contaminated. Avoid long time to exposure to skin.

Available packing

Black,white available, customer tailored, in 310-ml 600ml, 5 or 55 gallon cartridges.

Storage shelf life

This product is non-dangerous goods, save in temperature below 27 ℃ in a cool dry place for a period of 12 months.