SV High Performance Assembly Adhesive

Product Description

FEATURES

1.Good filling and flowing properties

2.Easy to process

3.High strength and high module

PACKAGING

BASIC USES

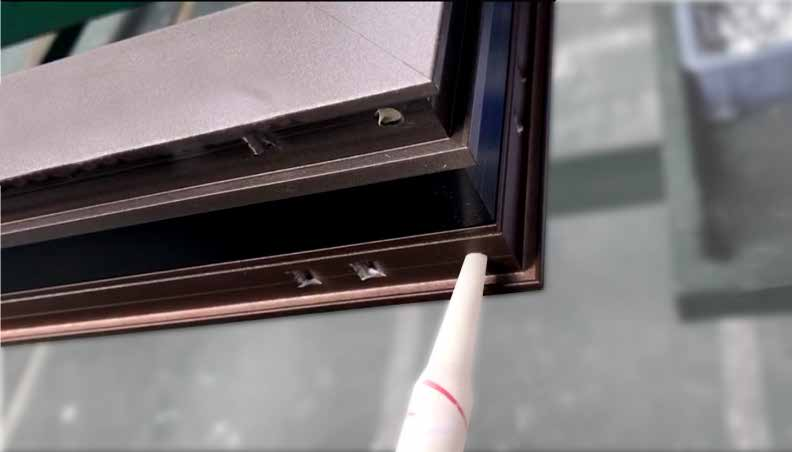

1.Injection system for corner connection of aluminum doors and windows, it has high hardness, toughness, excellent caulking performance;

2.used for bonding e.g. corner connections for frame profiles that are usually used for windows and doors.

3.Adhesion for wood-aluminum compounding, aluminum-plastic compounding, steel-plastic co-extrusion;

4. Adhesion for aluminum alloy, nylon, metal and so on.

TYPICAL PROPERTIES

These values are not intended for use in preparing specifications

| PROPERTY | STANDARD/UNITS | VALUE | |

| Appearance | Visual | White, uniform and fine,no particles | |

| Sagging | ≤3 mm | 0-2 | |

| Mixing proportion volume ratio | v:v | 100:100 | |

| Applicable period | ≥10 min | 15 | |

| Tack free time | min | 30±5 | |

| Bending test (bending deformation) | ≥4 mm | > 15 (breakable) | |

|

Hardness |

1H | ≥60(Shore D) | 2 |

| 2H | -- | 16 | |

| 3H | -- | 32 | |

| 4H | -- | 50 | |

| 5H | -- | 54 | |

| 24H | ≥60(Shore D) | >70 | |

| 7day | > 75 | ||

| Shear strength | 24H | ≥2 MPa | ≥4 |

| 7day | ≥3 Mpa | ≥6 | |

| Temperature resistance | ℃ | -50~+100 | |

| Service temperature | ℃ | 5~+40 | |

| Shelf life | Month | 9 | |

| The above data are tested data under the standard state; the test data are for reference only.Executive Standard: JC/T 25620-2002 "Structural Sealant for Building Doors and Windows | |||

CURE TIME

The curing of SV High Performance Assembly Adhesive takes place by a chemical reaction of the two components. Higher temperatures speed up the curing process and lower slow it down. In big bead applications, the generated heat of exothermic reaction can speed up the cure,reducing the pot-life.

STORAGE AND SHELF LIFE

Should be stored at or below 27℃ in original unopened containers. It has a shelf life of 12 months from the date of manufacture.