SV3350 Rapid Set Self Leveling Road Silicone Sealant for Expansion Joints

Product Description

MOQ:1000 Pieces

PACKAGING

600ML/piece, 25kg/barrel

COLOURS

SV628 is available in black, gray, white and other customized colours.

FEATURES

- Excellent Weather Resistance: Maintains stable performance within a temperature range of -60°C to 200°C.

- Superior Adhesion and Waterproofing: Provides exceptional bonding capabilities and waterproofing properties.

- Unique Siloxane Molecular Structure: Offers a lifespan far exceeding traditional organic materials such as asphalt and polyurethane.

- Strong UV Resistance and Anti-Aging Performance: Resistant to intense ultraviolet radiation and exhibits excellent aging resistance.

- Outstanding Elasticity and Recovery Rate: Features high elasticity and tensile recovery, effectively protecting concrete bonding surfaces.

- Excellent Resistance to Acids, Alkalis, and Salts: Withstands erosion from de-icing agents, engine oil, and various solvents used on road surfaces.

- Single-Component Curing and Self-Leveling: Simplifies application with its one-component curing process and self-leveling characteristics.

Safety and Environmental Impact: This product is non-toxic and safe for skin contact, causing no adverse effects. It is environmentally friendly!

Typical Properties

These values are not intended for use in preparing specifications

| Serial number | project | Standard regulations | Test results | Single Assessment | ||

| 1 | Appearance | Delicate, uniform paste or viscous liquid | Fine, uniform viscous liquid | qualified | ||

| 2 | Surface drying time (h) | ≤16 | 1.3 | qualified | ||

| 3 | Stretch Adhesion | Tensile modulus MPa |

2 3ºC | ≤0.4 and ≤0.6 |

0.1 | qualified |

| -2 0ºC | 0.1 | |||||

| 4 | Elastic recovery rate (%) | ≥80 | 89 | qualified | ||

| 5 | Adhesion to concrete (tension and compression range is +30%--12.5%) |

After immersion | No damage | qualified | ||

| After oil immersion | No damage | qualified | ||||

| After artificial aging | No damage | qualified | ||||

| 6 | Heating mass loss rate (%) | ≤6 | 3.5 | qualified | ||

| 7 | Mass loss rate after oil immersion (%) | ≤3 | 2 | qualified | ||

1. Bonding and sealing joints, including expansion, settlement, and pavement cuts in roads, airport runways, plazas, wall penetrations, docks, roofing systems, and underground parking.

2. Installing anti-leak seals in oil refineries and chemical processing plants.

3. Bonding and sealing epoxy flooring and painted surfaces, as well as various industrial flooring solutions.

4. Ensuring superior bonding, sealing, and maintenance for a range of materials, including concrete, timber, metal, PVC, ceramics, and more.

Construction Instructions

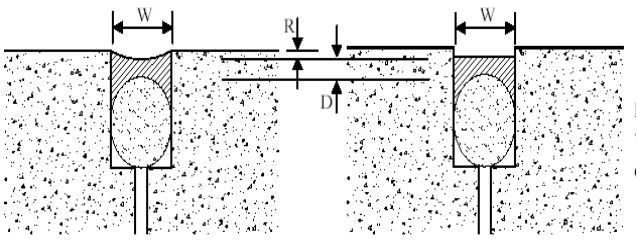

1. Cleaning of the Joints Ensure that construction is carried out in relatively dry weather. Prior to application, clean the joints thoroughly. Use a modified joint cleaning machine to grind the walls of the expansion joints. For excess soil at the bottom of the joint, use a homemade iron hook for loosening treatment, followed by using a blower to clean the base. Once the joint is relatively dry, embed the backer material (closed-cell polyethylene board) and apply masking tape on the flat surfaces adjacent to the expansion joint to prevent contamination. (For old joints, it is essential to remove the old sealant from both sides of the joint, especially if different types of sealants are present, as this will affect the bonding of the new product with the cement joint.)

2. Sealing Process For expansion joints ranging from 4mm to 20mm, it is recommended to use a caulking gun for injection. Pour the sealant into an aluminum caulking gun promptly, install the nozzle, cut a suitable hole with a knife, align the nozzle with the expansion joint, press against the top edge of the foam rod, and apply the sealant evenly. For joints wider than 20mm, a caulking gun or crack sealing machine can be used. The entire process of applying the sealant should be completed within the working time, which refers to the period from opening the package, removing the sealant, loading it into the applicator until the completion of application, typically between 60 to 90 minutes. If the weather is hot and humidity is high, the working time may be shortened, so pay attention to your operation time; otherwise, the sealant will become increasingly viscous and difficult to apply. After completion of work, wait for the sealant to cure before removing the masking tape.

3. Requirements for Sealant Depth Given that SV 3350 self-leveling silicone road sealant features ultra-low modulus, excellent UV resistance, and outstanding displacement capability, and has been validated through numerous practical projects, it is recommended that contractors follow these guidelines:

Contact Us

Shanghai Siway Curtain Material Co.Ltd

No.1 Puhui Road ,Songjiang Dist,Shanghai,CHINA Tel: +86 21 37682288

Fax:+86 21 37682288