SV8890 Two-component Silicone Structural Glazing Sealant

Product Description

FEATURES

1. None sag

2. Adjustable working time

3. Excellent adhesion to most building substrates

4. High bonding strength and modulus

5. 25%movement capability

6. Silicone durability

PACKAGING

Component A(Base): 190L, Component B(Catalyst) :19L

Component A(Base):270kg, Component B(Catalyst): 20kg

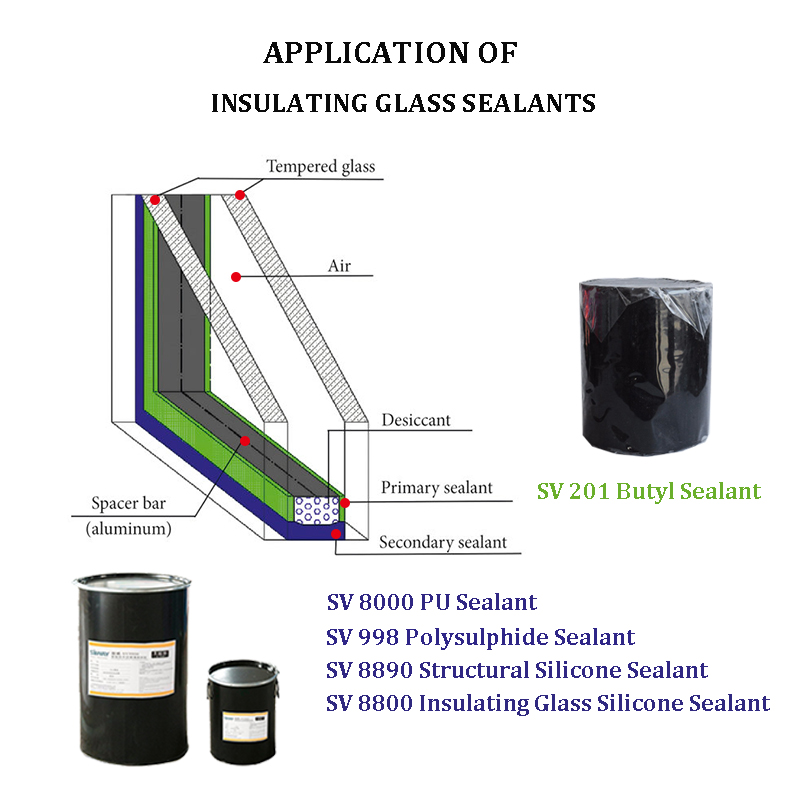

BASIC USES

SV8890 Pu sealant is designed for weatherseal and perimeter seal application of insulating glass.

COLOURS

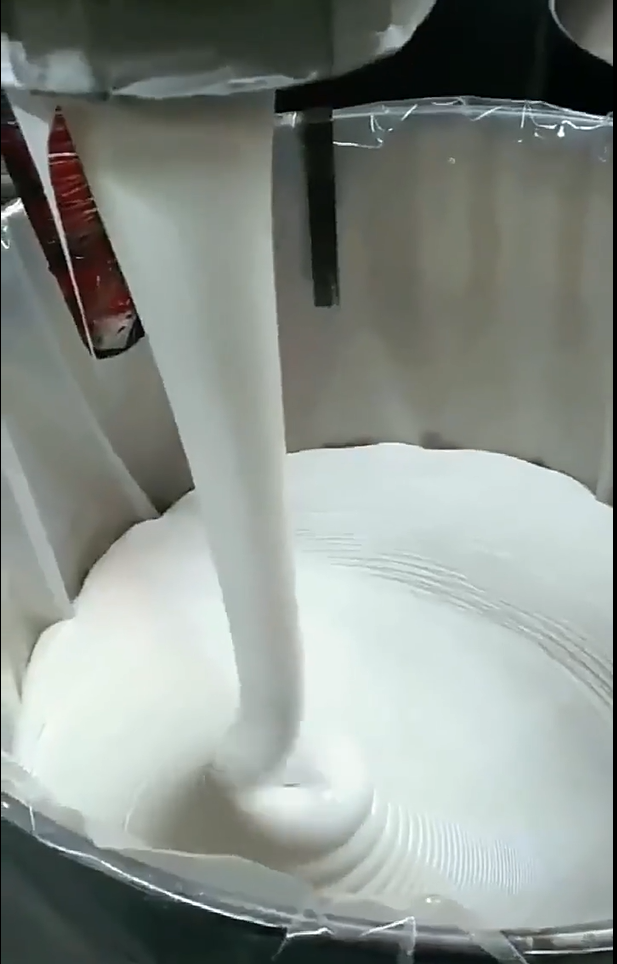

SV8890is available in black, gray, white and other customized colours.

TYPICAL PROPERTIES

These values are not intended for use in preparing specifications

| Test project | Unit | Value |

| Flow, sagging or vertical flow | mm | 0 |

| Operating time | min | 20 |

| surface drying time(25℃,50%R.H.) | min | 40-60 |

| Durometer Hardness | Shore A | 20-60 |

| At 23 ℃ maximum tensile strength elongation | % | ≥100 |

| Tensile strength(23℃) | Mpa | 0.9 |

| Tensile strength(90℃) | Mpa | 0.68 |

| Tensile strength(-30℃) | Mpa | 0.68 |

| Tensile strength(flooding) | Mpa | 0.68 |

| Tensile strength(flooding - ultraviolet) | Mpa | 0.68 |

| Bond damage area | % | 5 |

| Thermal aging(thermal weight loss) | % | ≤5 |

| Thermal aging(crack) | No | |

| Thermal aging(efflorescence) | No |

Product Information

CURE TIME

As exposed to air, SV8890 begins to cure inward from surface. Its tack free time is about 50 minutes; the full and optimal adhesion depends on the sealant depth.

SPECIFICATIONS

SV8890 is designed to meet or even exceed the requirements of:

Chinese national specification GB/T 14683-2003 20HM

STORAGE AND SHELF LIFE

SV8890 should be stored at or below 27℃ in original unopened containers. It has a shelf life of 12 months from the date of manufacture.

HOW TO USE

Surface Preparation

Clean all joints removing all foreign matter and contaminants such as oil, grease, dust, water, frost, old sealants, surface dirt, or glazing compounds and protective coatings.

Application Method

Mask areas adjacent to joints to ensure neat sealant lines. Apply SV8890 in a continuous operation using dispensing guns. Before a skin forms, tool the sealant with light pressure to spread the sealant against the joint surfaces. Remove masking tape as soon as the bead is tooled.

TECHNICAL SERVICES

Complete technical information and literature, adhesion testing, and compatibility testing are available from Siway.

SAFETY INFORMATION

● SV8890 is a chemical product, not edible, no implantation into body and should be kept away from children.

● Cured silicone rubber can be handled without any risk to health.

● Should uncured silicone sealant contact with eyes, rinse thoroughly with water and seek medical treatment if irritation persists.

● Avoid prolonged exposure of skin to uncured silicone sealant.

● Good ventilation is necessary for work and cure places.

DISCLAIMER

The information presented herein is offered in good faith and is believed to be accurate. However, because conditions and methods of using our products are beyond our control, this information should not be used in substitution for customer’s tests to ensure that our products are safe, effective, and fully satisfactory for specific applications.